Foreign Insulators

by Marilyn Albers

Reprinted from "INSULATORS - Crown Jewels of the Wire", December 1983, page 16

Hodge Podge Month

The Story

of a Company

Back in the January 1980 issue of Crown Jewels my column carried a

brief description of NZI (New Zealand Insulators Limited), a New Zealand based

manufacturer of porcelain insulators, which has two plants located in the

district of Canterbury, South Island, one in Temukah and the other in Ashburton.

We learned that NZI produces many types of insulators: high and low voltage pin

types, bobbins and reels, strain insulators, fuses, wiring accessories, etc.,

and that most of these insulators are glazed a lustrous chocolate brown. All

that was known to me at that time was that the eighty year old company had had a

small beginning, but with subsequent growth and an increase in technical

ability, NZI is today the leader of the technical ceramic industry in New

Zealand. I had no other details of the company's history.

Then a few weeks ago,

Gene Calman (San Diego, California) mailed me some additional information he'd

come across, and I learned that in 1971 a section of the Temuka plant, known as

Temuka Potteries, began making what is known as "Temuka Stoneware".

This is a lovely and durable type of oven to table ware and kitchen ware made

from vitrifying clay taken from Temuka Pottery's own quarry in South Canterbury.

Gene also supplied me with a company history, which I have found quite

interesting. It's always fun to find a missing part of the puzzle, and I'd like

to share this with you.

COMPANY HISTORY OF NEW ZEALAND INSULATORS LIMITED-TEMUKA

The land on which the factory now stands, together with much of the surrounding

land, was bought from the Government by Mr. Samuel Hewlings, a surveyor, in

1861. The land was described as swamp, covered with Ti-tree and flax.

There is

little to support the view that any business was set up on the land, although in

the book "A South Canterbury History", an incident is recalled of how

a Mr. George Leven "swam a horse over the fence of a brickyard owned by Mr.

Joseph Whitehead". Since this was in 1868, when the whole of Temuka was

flooded, it is difficult to establish where that brickyard was located.

Samuel

Hewlings began selling his land, and sections were sold in 1874, 1876 and 1878,

but again there is no evidence that businesses were set up on the land, much of

which changed hands frequently.

Archives of the local newspaper show that a Mr.

William Hoare acquired a piece of this land in 1894 to make bricks. It has been

suggested that these may have been sun-dried, but this cannot be substantiated.

On January 28, 1899, a sale notice appeared in the newspaper that on that day, a

"Brick-makers Business and Plant" in estate of the late William Hoare,

would be sold. Included in the sale was 1-3/4 acres of land, 2 kilns (type not

stated), pumps, etc. A significant statement was added, quote, "Good demand

for bricks in the district, and no other brickworks in the locality",

unquote. The business was believed to have been bought by Frederick Collier, a

Temuka Carrier.

On February 3, 1900, a further notice appeared in the

"Temuka Leader", stating that, quote, "Having secured a capital

section from Mr. James Davis, containing the best of clays and also the

necessary plant, I shall be prepared to supply bricks in any quantity at current

rates", unquote. He goes on to say that his first kiln would be ready in 4

to 6 weeks. This notice was signed W. Hoare, presumably the son of the late

William Hoare.

There are unsubstantiated reports that about this time, thoughts

were turning to the making of drain pipes from the clay to drain the surrounding

low lying areas. It is believed "Hoare & Page" undertook this

work.

In October 1903, there appeared a notice inserted by William Berry,

advising that having taken over the brickyard carried on by Hoare & Page of

Temuka, he hoped to supply bricks to the people in the district.

Competition

must have been fierce, because also in October 1903, Fred Collier inserted a

notice in the same newspaper, stating that, quote, "Having just built a new

and up-to-date kiln, and just burnt the first of season's bricks, I am prepared

to supply bricks in small or large quantities", unquote.

There is little

evidence of further activity, although land continued to be bought and sold,

until February 1916, when a number of sections were bought by the "Temuka

Pipe Works Company Ltd."

However, in April of the same year, the title was

transferred to the "Canterbury Pipe and Tile Co. Ltd." The name of

this company was changed to the Dominion Porcelain and Tile Industries Ltd., but

no date is shown on the document. The company began making insulators in 1918,

and a Mr. Brown and a Mr. Ballantyne are credited with making the first of

these.

In February 1924 the company was taken over by the National Electrical

& Engineering Co. Ltd. (NEECO), and became New Zealand Insulators Limited.

Little is known about the company's progress until World War II, when the output

of communication insulators soared, millions of these were destined for India.

In 1942, Mr. Tom Lovett took over the factory as Manager, and from this point,

the development in the manufacture of insulators really commenced after a move

by the New Zealand Government towards the supply of communication insulators to

British Standard Specifications. During this period the "Bottle Kiln"

was still the main firing medium and a total of nine were in operation. The

company, however, did operate an electric kiln in addition from 1943.

In March

1950, the main factory building burned down, and the cleared site made possible

a re-building program which permitted the move to oil fired tunnel kilns, the

first of which came into use in June 1954.

A further fire in 1959 destroyed the

electric kiln, and the decision was made not to reinstate it, but to hasten the

completion of the second oil-fired kiln then under construction. Both kilns were

130 ft. long, and extended to 150 ft. in 1975 and 1976. In 1964, the company saw

the introduction of several highly trained technical staff from the U.K. This

coincided with the building of a 14,000 sq. ft. factory at Tinwald, Ashburton,

for the production of metal parts and plastic components used in the assembly of

fuses, lamp holders, switches, connector blocks, etc. This was later extended.

Late in 1965, a new Toolroom and Drawing Office were built in Temuka.

The

company was bought by the Cable Price Downer Group in 1967, and New Zealand

Insulators became an independent subsidiary within this group.

Although a

limited range of domestic pottery was manufactured from 1920 onwards, these

included electric jugs, hot water bottles, bread crocks and vases, it was in

1971 that production of our distinctive domestic stoneware began. The company

now supplies a comprehensive range of tableware and ovenware for both the home

and overseas markets. So great has been the demand for these products, that a

new 10,000 sq. ft. extension was opened in March 1977, solely for the production

of Temuka Stoneware.

The name "Temuka" is shortened from Te-umu-kaha,

which means "The Fierce Oven". A place where local *Maoris dug large

pit-type ovens for communal cooking. Layers of leaves cover large heated stones

in these ovens -- with flax baskets of food being placed on top -- completely

covered with layers of flax and finally earth, until food was steam-cooked (few

hours) then opened. Whole pigs, vegetables, etc. were cooked in this method.

The

most important aspect of the company's business remains the servicing of the

Electrical Distribution Industry with its major commitment of resources being

towards the manufacture of insulators for service on distribution and

transmission lines from 440 volt up to 220 Kv.

Today the factory employs 400

people in its Temuka and Ashburton plants, and is not only an efficient New

Zealand industry, but is important to the national economy in that it makes

essential products largely from local raw materials, thus making and saving

substantial overseas funds.

*Indians

Insulator Ash Trays

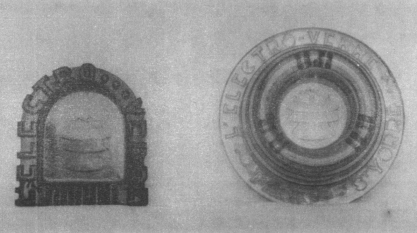

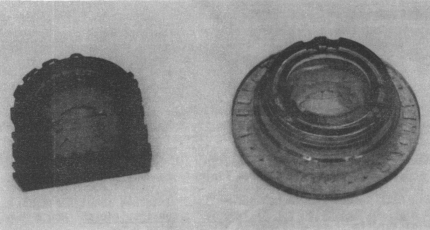

I got a real thrill a while back

when UPS brought me a box from Tom Moulton (Ballston Lake, New York). "What

on earth," I thought, "I don't remember ordering anything from him

recently." What a good insulator day it was when I opened the box and

discovered two French glass ash trays. Each one was slightly different, but both

had an embossed triple skirted insulator (like C.D. 378) at the center. Standing

out in raised letters around the edges of each ash tray were the words L'Electro

Verre, and the larger of the two also had the words Paris and St. Yorre. The

color is a green aqua, exactly like the dozens of L'Electro Verre insulators I've

seen. (You do learn to recognize it after a while. The same is true of any

specialty collector.) Undoubtedly the ash trays had been made up at one time as

gifts for existing or prospective customers and had probably come from the same

batch of glass that had been used to make insulators.

You probably remember that

L'Electro Verre was the name of a small French glass manufacturer that merged

with the Insulator Department of the Charbonneaux Glass works at the beginning

of 1959 in order to form the new Sediver Company. Today, many years later, that

company has grown into a great sales organization, known as Sediver

International, which exports French insulators to just about every corner of the

earth. Their headquarters and main sales office is in Paris.

Insulators marked

L'Electro Verre date before that 1959 merger. The present day insulators

marketed by Sediver are embossed E.I.V., which stands for Societe Europeene D'

Isolataurs en Verre, or loosely: European Society of glass makers. These are

manufactured by the Saint Gobain Glassworks in St. Yorre, which is a Sediver

subsidiary, but also a major shareholder.

I have no facts to support it, but

because the largest ash tray has on it the names Paris and St. Yorre, I would

guess that perhaps L'Electro Verre at one time occupied the same plant as does

Saint Gobain Glassworks, and Paris was probably their sales office.

I'm very

proud to have these ash trays, and what a perfect "go-with" they are!

When the box first arrived, there was a note with them from Tom asking, "Do

you know of anyone who collects this sort of thing?" He'd found them at a

flea market, and he had to be smiling when he wrote this, knowing I would go

straight up. And I did. One more time, Tom, thanks for sending them!

"Copper tops" from Australia

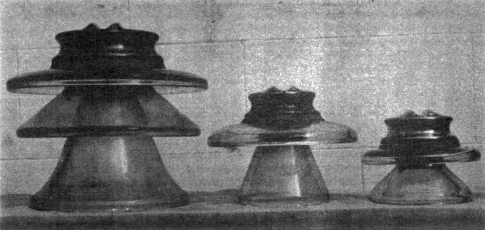

In the picture following you see three

large glass power insulators with copper tops. These are from the collection of

Laura Van der Endt (Sidney, Australia).

11-3/4 x 10-1/2

(width) (height) |

9 x 7-1/2

(width) (height) |

7-1/8 x 5-1/2

(width) (height) |

Laura tells me these were found in only

one place in Australia, and she's understandably not saying where! There are no

markings on them at all, but after looking at an insulator catalogue put out by

Pilkington Brothers (St. Helens, England) and seeing the striking resemblance to

three of their styles, also with copper tops, Mr. N. R. Woodward (Houston,

Texas) suggested that they might be unmarked Pilkington insulators. That company

did certainly export insulators to all parts of the world.

I now have duplicates

of the two smaller insulators in my own collection, so we are able to examine

them first hand. The pale ice green tint of the glass is identical to a

suspension disc I have that is definitely a Pilkington specimen, because it is

marked with their trade name of "Armourlight" to identify it as

toughened glass.

In the photo, the largest insulator at the left has not yet

been assigned a C.D. number (or been identified as an already existing one), but

the medium size one (center) is now C.D. 344.2, and the smallest (right) is C.D.

343.2. When the copper tops are shined up, these are just beautiful! If and when

we ever establish the identity of the manufacturer of these insulators, we will

let you know. As a point of interest, Pilkington Brothers stopped production of

high voltage insulators in 1970 when they merged with Sediver International.

However, they do still have a plant in South Africa which continues to

manufacture the high voltage pin types. Small world!

|